The Unmatched Performance of 2-Phase Immersion Cooling

Liquid Cooling for Hyperscale, Edge, High Performance Computing, and Cryptocurrency Mining

2-Phase Immersion Cooling Explained

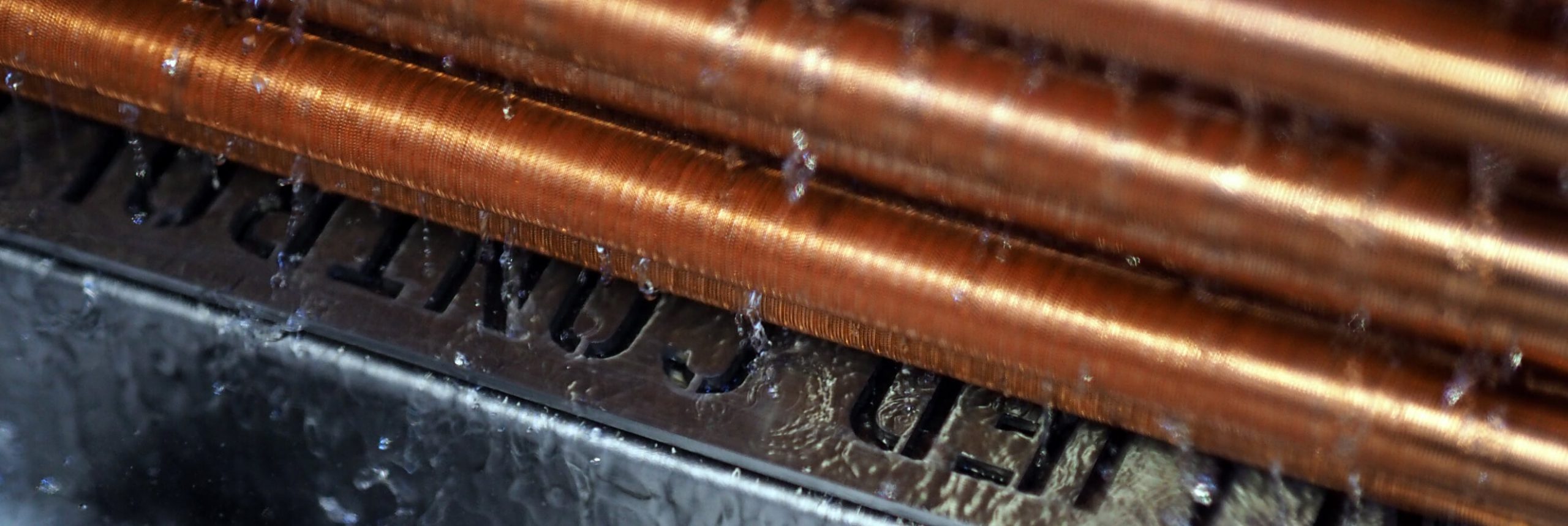

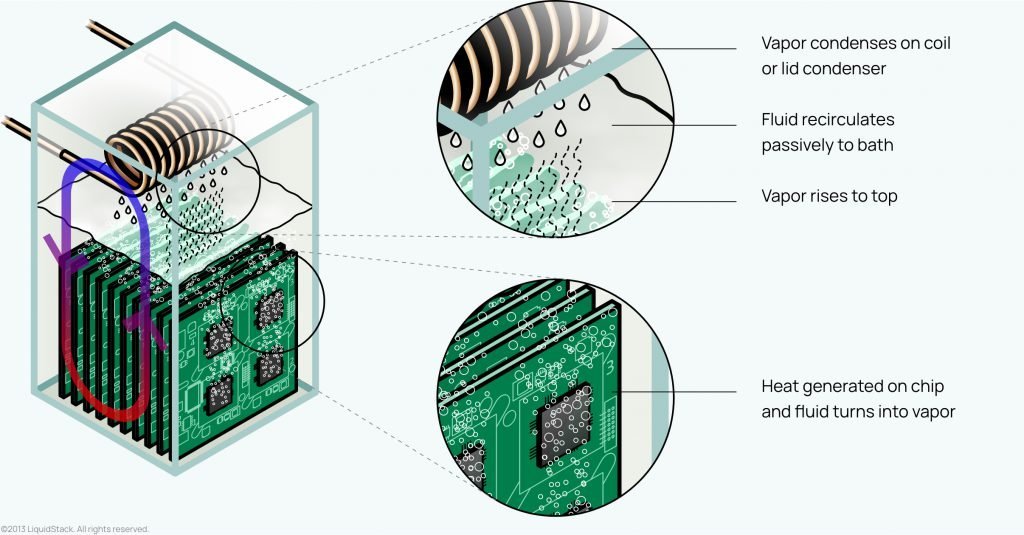

2-phase immersion cooling works by submerging compute equipment in dielectric liquid. The compute equipment heat transfer causes the fluid to boil and turn into vapor. That’s what makes it two-phase. The vapor then rises and condenses on a heat exchanger. There, it cools, returns to a liquid state and drips back into the tank. The process repeats in a passive cycle, without pumps or mechanical equipment, except for a small pump that circulates the fluid through a filter.

- Electronics are completely immersed in dielectric (non-conductive) fluid with no need for bulky heat sinks or fans

- Chip temperatures rise until the fluid boils

- Phase 1 of heat transfer occurs as the hot vapor rises

- Phase 2 occurs as the vapor condenses on a specialized coil

- Condensed fluid falls back into the tank as droplets, beginning the cycle again

- The phase change of boiling leads to automatic convection and higher heat rejection capacity

- The cooling process is entirely passive, with no pumps or moving parts required to reject IT heat

The Passive 2-Phase Immersion Cooling Cycle

How Cooling Methods Differ

| Practical for high-powered chips or racks | Low TCO, no duplicate cooling infrastructure | Easy and fast maintenance of IT equipment | Future-proof (not tied to IT equipment) | No fire hazard or mess from oil | |

|---|---|---|---|---|---|

| Air Cooling | |||||

| Direct Liquid Cooling (Cold Plate/Chip) | |||||

| Oil-Based 1-Phase Immersion Cooling | |||||

| IT-Chassis Immersion Cooling | |||||

| Tank-Based 2-Phase Immersion Cooling |